Understanding the Role of PCBA Manufacturers in Modern Electronics

In today’s fast-paced digital world, electronics are the foundation of everything from smartphones to industrial automation. Behind these smart devices lies a complex system of circuitry powered by high-quality printed circuit board assemblies (PCBAs). A PCBA manufacturer is not just a supplier — they are the backbone of innovation, ensuring functionality, reliability, and performance in every electronic device. For businesses and engineers alike, choosing the right PCBA partner is crucial to the success of any tech-driven project.

What Is PCBA and Why Does It Matter?

A Printed Circuit Board Assembly (PCBA) refers to the complete process of assembling electronic components onto a bare PCB. This includes soldering, surface mounting, testing, and quality checks. Whether you’re designing a wearable fitness tracker or a robotics control system, the reliability of the PCBA determines the longevity and safety of your product.

See also: Understanding the Role of PCBA Manufacturers in Modern Electronics

Key Services Offered by a Professional PCBA Manufacturer

A trusted PCBA manufacturer like PCBA manufacturer offers end-to-end services, from prototyping to volume production. Let’s look at some core services:

1. PCB Fabrication

This is the initial stage where the board is designed and fabricated according to the client’s specifications. Fabrication involves:

. Multilayer PCB production (2 to 20+ layers)

. Flexible and Rigid-Flex PCB options

. High-frequency PCBs for RF and microwave applications

. Material selection including FR4, Rogers, and polyimide substrates

2. PCB Assembly (PCBA)

Once the board is fabricated, the next step is component mounting:

. Surface Mount Technology (SMT)

. Through-hole and mixed assembly

. BGA, QFN, and fine-pitch component handling

. Automated optical inspection (AOI) and X-ray inspections

3. Turnkey Solutions

Companies like Global Well PCBA also offer turnkey services, which include:

. Component sourcing and procurement

. Custom box builds and cable assemblies

. Functional testing and burn-in testing

. Conformal coating for environmental protection

Why Industry Experience and Advanced Capabilities Matter

Not all PCBA manufacturers are created equal. A few things to consider when evaluating one:

. Certifications: Look for ISO9001, ISO13485 (for medical devices), and IPC standards compliance.

. Engineering Support: Some projects require DFM (Design for Manufacturing) services to minimize errors before production.

. Scalability: From rapid prototyping to large-volume production runs.

. On-time Delivery: Especially critical for industries with tight product cycles like consumer electronics or IoT.

. Global Well PCBA brings all of these to the table. With years of experience in the electronics manufacturing field, they have supported projects in aerospace, medical, automotive, telecommunications, and consumer electronics.

Emerging Trends in the PCB and PCBA Industry

As technology evolves, so does the demand for more advanced and compact electronics. Here are some key trends PCBA manufacturers must be ready to handle:

1. Miniaturization and High-Density Interconnects (HDI)

Smartphones, wearables, and medical implants all require smaller yet more powerful boards. HDI PCBs offer multiple layers and tighter trace routing, requiring specialized assembly capabilities.

2. Rigid-Flex PCB Solutions

Rigid-flex PCBs combine the best of both rigid boards and flexible circuits. They’re used in aerospace, military equipment, and foldable devices. Manufacturing and assembling these boards requires high precision and technical knowledge.

3. Green Manufacturing

There’s a rising demand for RoHS (Restriction of Hazardous Substances) compliance and eco-friendly production practices. Partnering with a PCBA manufacturer that emphasizes green manufacturing, like globalwellpcba.com, is essential for companies with global distribution goals.

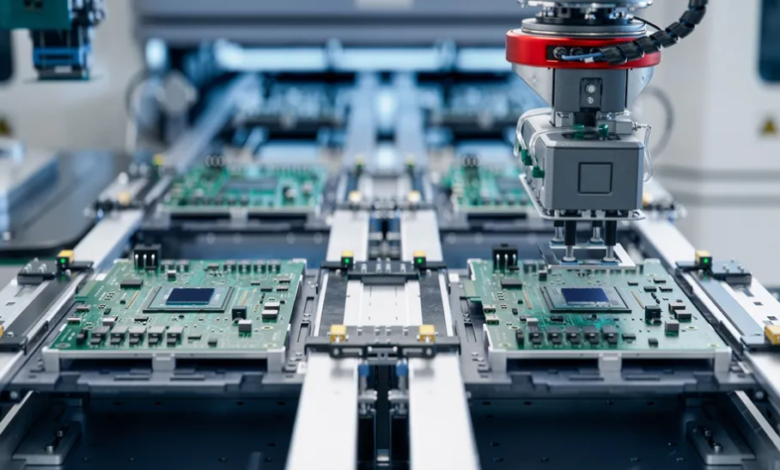

4. AI and Automation in Manufacturing

To reduce errors and increase efficiency, many modern PCBA facilities now use machine learning and AI tools for inspection, pick-and-place programming, and quality assurance.

Industries That Rely Heavily on PCBA Services

A wide range of sectors depends on PCBA manufacturers for high-performance electronics:

1. Telecommunications

Devices like routers, antennas, modems, and satellite systems require durable and heat-resistant PCBs. These must perform reliably in high-frequency applications.

2. Medical Devices

From ECG machines to hearing aids, these electronics require precision, sterilizability, and strict regulatory compliance.

3. Automotive

Modern vehicles are smart. They rely on dozens of embedded PCBs for ADAS, infotainment systems, engine control units, and more.

4. Industrial Automation

Factory robots, CNC systems, and control units need PCBA solutions that can withstand vibration, dust, and temperature variations.

5. Consumer Electronics

Whether it’s your gaming controller or smart speaker, PCBA plays a critical role in delivering high-speed, compact, and efficient performance.

What Makes Global Well PCBA a Trusted Manufacturing Partner?

For those looking to develop cutting-edge electronic products, Global Well PCBA stands out for several reasons:

✅ One-Stop Solution

They handle everything from PCB design, fabrication, assembly, and component sourcing to testing and delivery. This helps reduce lead time and ensures product consistency.

✅ Global Shipping & Service

While based in China, they ship globally and cater to clients in the U.S., Europe, and Southeast Asia.

✅ Focus on Innovation

Whether you need High Frequency PCBs for radar systems or Rigid-Flex boards for aerospace equipment, Global Well PCBA has the technical expertise to deliver.

✅ Competitive Pricing

With full control over the supply chain and bulk component sourcing, they can offer highly competitive prices without compromising quality.

Tips for Choosing the Right PCBA Manufacturer

If you’re selecting a manufacturing partner for the first time, here are a few quick tips:

- Ask for a Prototype First – A sample run can reveal their manufacturing and quality control capabilities.

- Check Communication Responsiveness – Timely support is crucial during all stages of production.

- Review Certifications and Case Studies – Choose vendors who follow international standards.

- Understand Lead Times – Find out how quickly they can deliver based on your production scale.

Final Thoughts

In the dynamic world of electronics, your product is only as good as its assembly. Whether you’re launching a startup gadget or scaling up a robotics solution, choosing a capable and experienced PCBA manufacturer is non-negotiable.

If you’re looking for precision, innovation, and cost-efficiency in one package, Global Well PCBA is a trusted name to consider. Their extensive manufacturing expertise and commitment to high-quality production make them an ideal partner for electronics engineers, startups, and OEMs around the world.